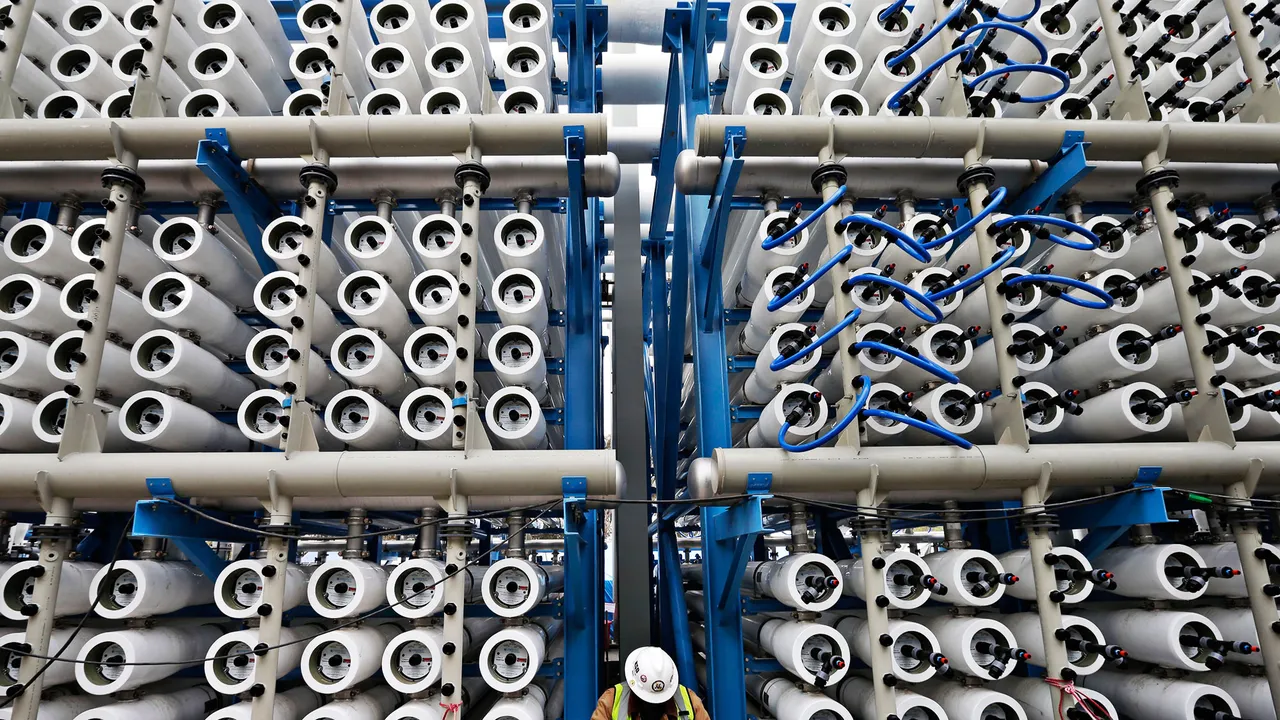

As I was researching different approaches to operating with and optimizing salt-water desalination, I came across this profound Stanford University article by Meagan Mauter, associate professor of civil and environmental engineering, that talked about “High-impact innovations for high-salinity membrane desalination.” It emphasizes the importance of quantitatively measuring the value of innovation (VoI) and efficiency of the desalination system compared to competing technologies.

They emphasize the point that it is unnecessary if not harmful to make improvements to the desalination process (membrane, RO process, energy use) if it significantly increases its cost as the differences will essentially cancel out.

The academic community prefers to use energy efficiency as its benchmark for preferred desalination alternative. On the other hand, industrial users often evaluate the cost efficiency based on the levelized cost of water (LCOW) or the sum of capital expenses (CAPEX) and operating expenses (OPEX). However, according to this article neither the academics nor the industrial users have comprehensively evaluated desalination technology designs as a function of feedwater salinity and desired water recovery or thoroughly considered multiobjective design targets.

For example, energy costs at RO facilities, which are significantly expensive (~$500,000 per year) only account for about 30% of the LCOW while the rest is accounted for by capital expenditures, replacements, and labor costs. What makes it even worse is that LCOW is volatile and liable to change.

The Stanford engineering team performed parametric sensitivity analysis on component performance in desalination process to guide the selection of desalination materials and manufacturing methods that reduce desalination system costs.

After performing stochastic value of innovation simulation analysis (SVoIA), a simulation of a system that has variables that can change stochastically with individual probabilities, they concluded: (1) VoI in technologies such as desalination is a complex function of multiple components (e.g. Pump efficiency, PX efficiency, Maximum pressure, Friction factor, Mass transport, Membrane structure parameters, Membrane salt permeability, and Membrane water permeability) and cannot be purely evaluated with LCOW, CAPEX, or OPEX, and (2) VoI of a component depends both on reducing that component’s costs and improving the performance of the other components.

Cost reductions resulting from improved seawater reverse osmosis (SWRO) technology could make seawater desalination a much more economical and attractive alternative for filtering and supplying potable drinking water in regions around the world, especially those with limited freshwater resources.

Questions:

- Using the new proposed approach for optimizing cost efficiency for certain materials, what changes would the Stanford engineering team make to SWRO plants in order to have more optimal efficiency and lower costs?

- Why is membrane permeability not a major contributor (~30%) in reducing the LCOW in RO processes such as Osmotically Assisted Reverse Osmosis (OARO)?

- How can the new Stanford cost optimization method be applied in the real world in water desalination?

- Was experimental data based on a defined membrane type or based on multiple membrane technologies (graphene, molybdenum disulfide, metal-organic framework)?

What I Like and Could Learn From Them:

I like the focus on economics of the desalination technology and impactful innovation at the component level to optimize performance and reduce costs. I would like to learn all the analytical techniques used including Monte Carlo simulation. Stanford has one of the best environmental engineering programs and is based in California, which is one of the largest desalination markets in the U.S.