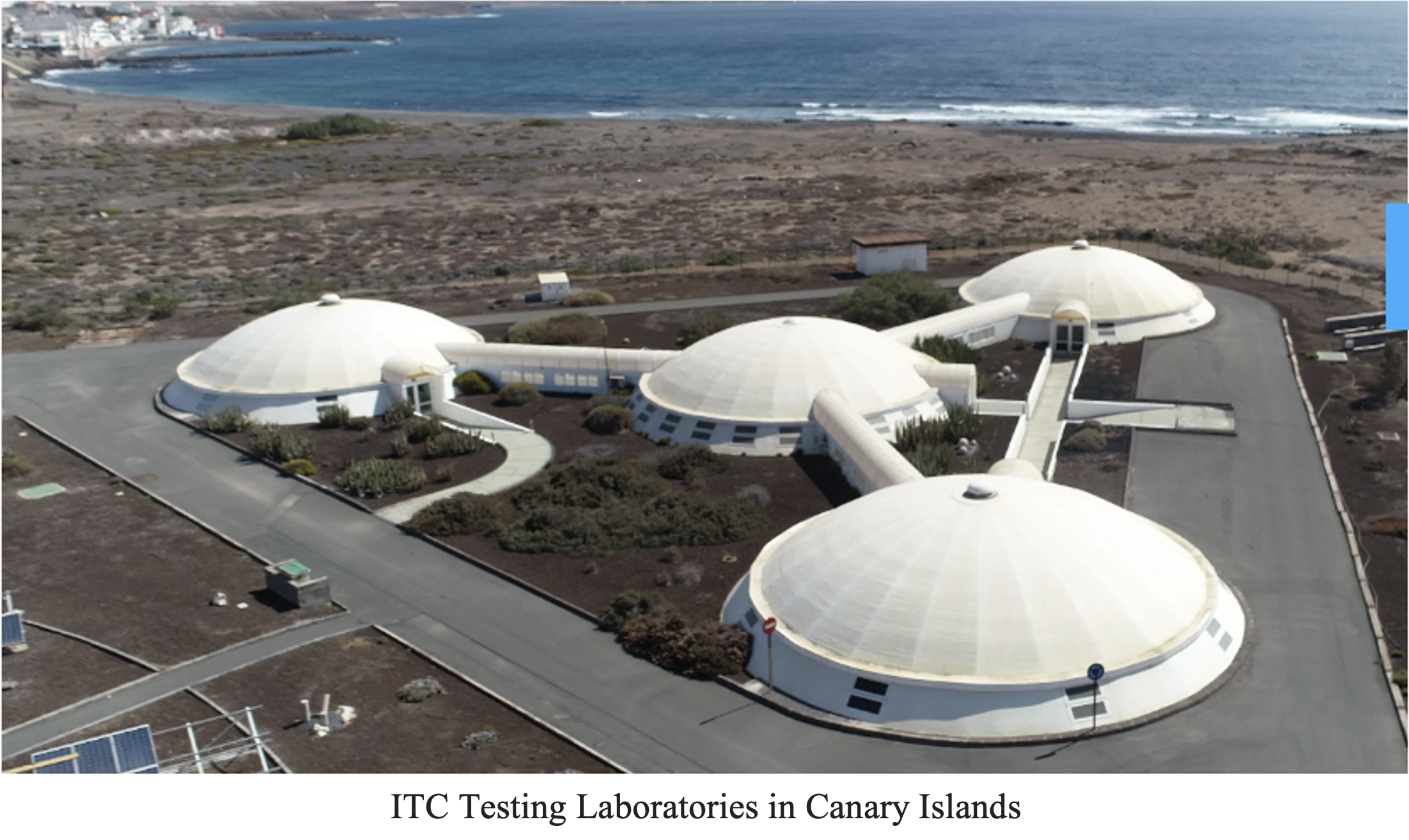

This summer (2022), I was fortunate to get an invitation to visit ITC’s (Canary Islands Institute of Technology) desalination facility in Pozo Izquierdo in Las Palmas de Gran Canaria. Not only is much of the island a UNESCO World Heritage site but also a volcanic island dotted with wind-powered turbines – make electricity while the wind blows!

ITC’s R&D team of 80 is committed to sustainability and focused on water technologies, renewable energy, environmental analysis, biotechnology, biomechanics and software engineering. ITC is funded by the Spanish government and European FEDER funds, and implements water treatment and renewable energy plants in the Canary Islands Archipelago and north Africa (Tunisia and Morocco).

ITC’s desalination testing labs spread over 100,000 m2 are ideal due to direct access to seawater and abundant renewable energy (annual average wind speed of 8 m/s, average daily solar radiation of 6 kWh/m2) and a brine discharge point. ITC boasts of 6 different portable off-grid reverse osmosis desalination units powered by solar and wind, with some having on-grid optionality. These pilot units (10-100 m3/day desalination water flux capacity) provide important feedback before launching larger units such as the ones that ITC has launched in Southern Spain and Africa (~1-2 units are launched per year).

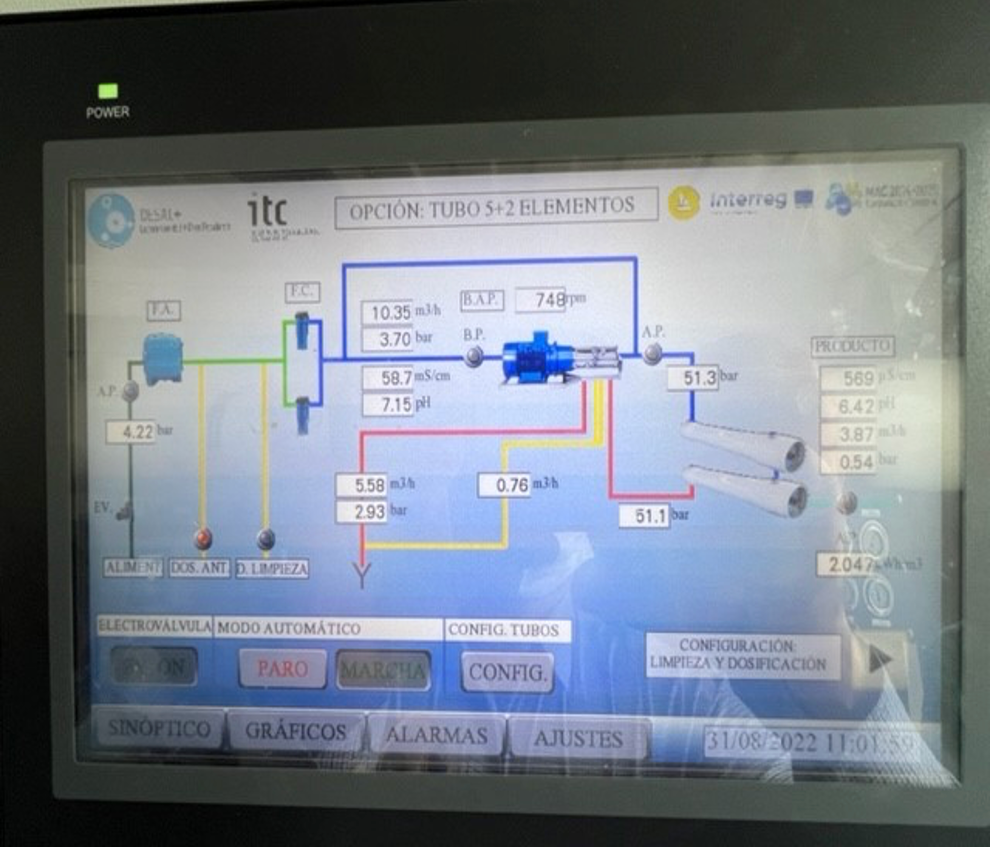

ITC’s team of Juan Antonio de la Fuente Bencomo and Pedro Jesús Cabrera Santana was generous with their time and gave me an informative tour including the practical and innovative things that they are doing with pilot desalination units, which I have not yet read in science journal articles on desalination. For example, hourly start and stop of incoming sea-water variable rate pump (including changing energy source) to study the impact on desalination performance (water flux and salt rejection).

Mr. de la Fuente advised that the cost of treating seawater in ITC’s pilot plant was Eur 0.60/m3 (subsidized) and Eur 1.20/m3 (without subsidies); and the energy consumption was 2.1-2.5 kWh/m3.

Testing Impact of Variable rate pumps on reverse osmosis performance

I have done independent work using artificial intelligence to select best nanoporous reverse osmosis membrane by training neural networks across a bunch of inputs (salt concentration, solute permeability coefficient, osmotic pressure, etc.) to optimize water flux and salt rejection. However, I was amazed to see how ITC’s Pedro Jesús Cabrera Santana (affiliated with University of Las Palmas) is applying artificial neural networks (ANNs) to manage the variable operation of a simple seawater reverse osmosis plant (Artificial neural networks applied to manage the variable operation of a simple seawater reverse osmosis plant – ScienceDirect). He studied the impact on reverse osmosis membrane and water flux (permeate recovery) by changing input variables such as fluctuating power input, seawater temperature, and conductivity of feedwater. Mr. Cabrera then incorporated ANNs into the control system of a seawater reverse osmosis desalination plant. His unit is now able to treat seawater under widely varying power conditions and feedwater characteristics – important practical application for military and eventually sustaining potable water on Earth and hopefully other planets!